SELF-CLEANING AIR CLEANING BLOWERS™

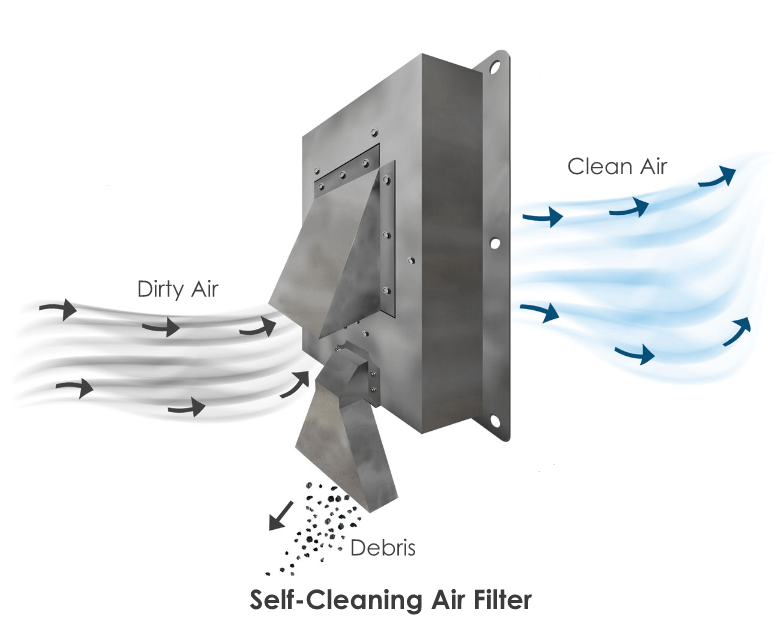

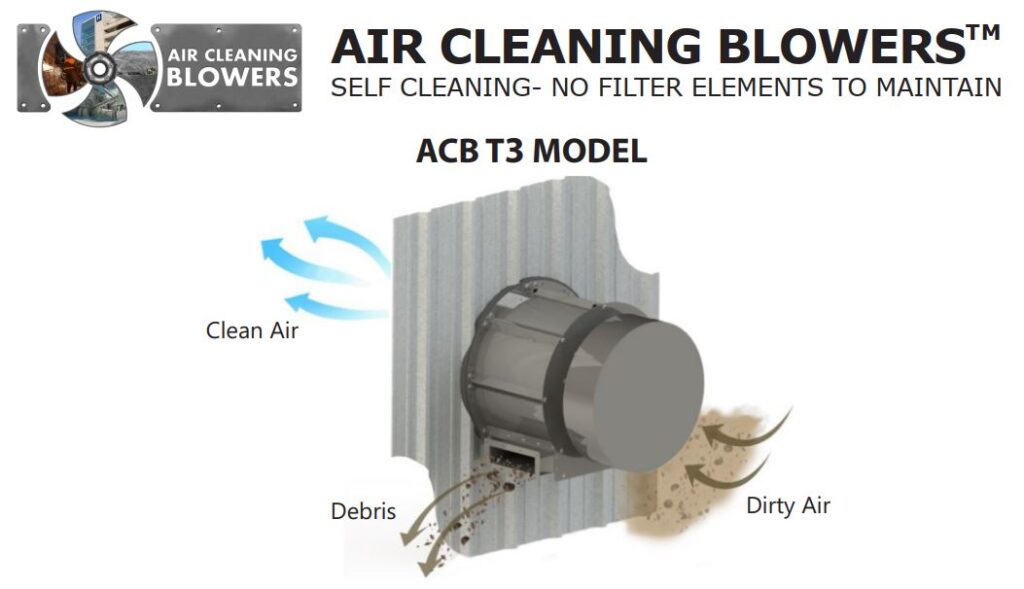

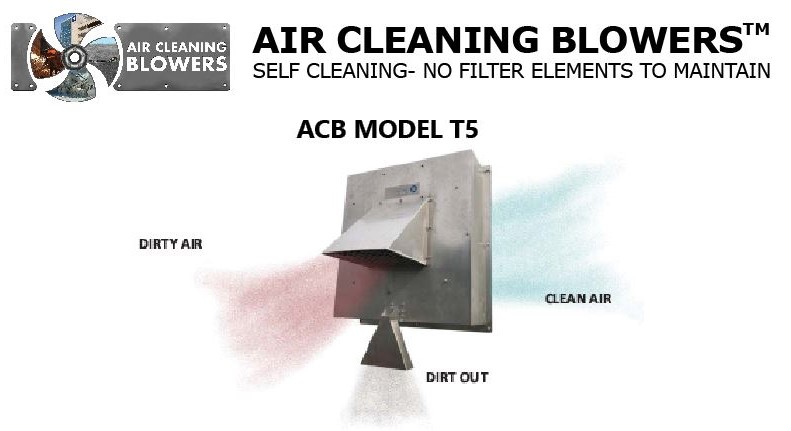

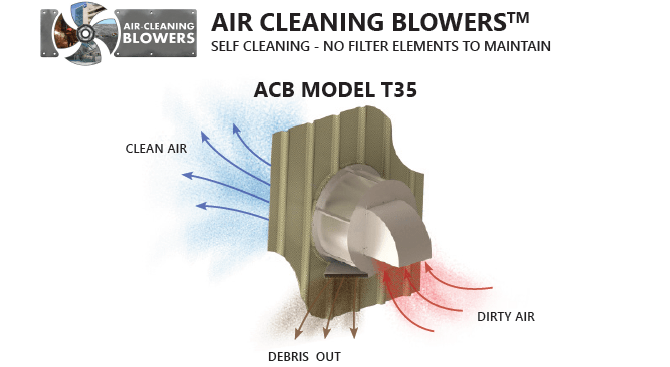

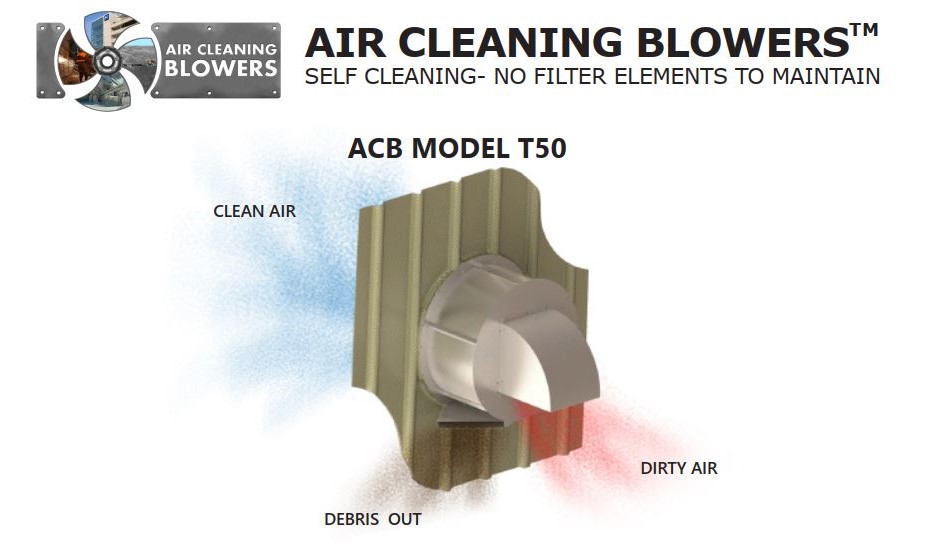

ACBs offer a modern solution that stands apart from traditional filter systems. Unlike their predecessors, ACBs do not rely on filter media or accumulate dust and dirt. This unique approach ensures consistent airflow, air pressure, quality, and electrical consumption with minimal maintenance. Whether for ventilation, pressurization, exhaust, or air feeding purposes, ACBs deliver clean air efficiently. The reason behind this efficiency is simple: most users prioritize clean air over collecting dirt. With ACBs, it’s all about providing pristine air without the hassle of debris collection.

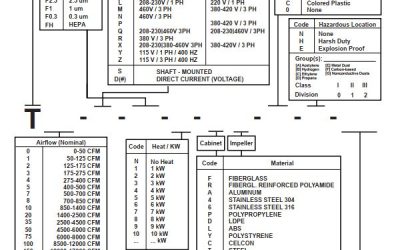

PRODUCT SPECIFICATION & NOMENCLATURE

- At Air Cleaning Blowers, LLC, we prioritize meeting our clients’ unique needs and preferences. With our “Build Your ACB Model” tool, also known as the Nomenclature, you can customize your ACB unit by selecting from the provided data. If you prefer our standard models, you can review the Product Specification Sheets below and submit an ACB Request Proposal to place your order today!

- We developed a simple to use Model Number Nomenclature to assist in building your specially designed Air Cleaning Blower unit. Please review our existing Product Sheets to reference certain features and adaptions.

TYPICAL MODEL OPTIONS FOR AIR CLEANING BLOWERS™

Patent #9,259,675. #10,118,115. #10,493,390. Others pending. CAGE Code: 7ZFZ0

CONSTRUCTION

Interior frame & wall sleeve constructed of stainless steel— Type 304 or 316—with other materials optional.

Variable or constant speed models

Many power sources: A/C (50 or 60 Hz, single and 3 phase) and D/C current, motor shafts, direct drive or pulleys

Units meet NEMA 4, NEMA 4X, IP54 and IP55 standards.

Self contained to facilitate and speed installation; can even be portable.

ADDITIONAL FEATURES

Units can include corrosion-resistant, heavy-duty electrical-resistance heating elements or heat exchangers, as option.

Adaptation for mounting in ducts and/or to connect to downstream special media such as activated carbon and/or to provide pre-cleaning and pressurization for air conditioners.

APPLICATIONS

• Agricultural Equipment and Grain Elevators

• Air Compressors

• Bulk Solids and Powder Conveyors & Hoppers

• Cell Towers and Communications Relay Stations

• Clean Rooms

• Coal Mines and Coke Plants

• Control Rooms and Pulpits

• Conveyors and Silo Loaders

• Data Centers

• Hotels and Convention Centers

• Electrical Buildings/Enclosures (MCCs; Control Panels)

• Evaporative (Swamp) Coolers

• Food Processors

• Foundries

• Hospitals—Modular and Traditional

• Locomotives and Passenger/ Freight Rail Cars

• Military Vehicles, Electronics and Magazines

• Mining and Tunneling Equipment

• Modular and Inflatable Buildings

• Motor Control Centers and Sub-Stations

• Office and Other LEEDs Buildings

• Pharmaceutical Production

• Power Plants—Fossil Fuel and Nuclear

• Recycling Facilities

• Sawmills

• Steel, Aluminum and Paper Mills

• Warehouses