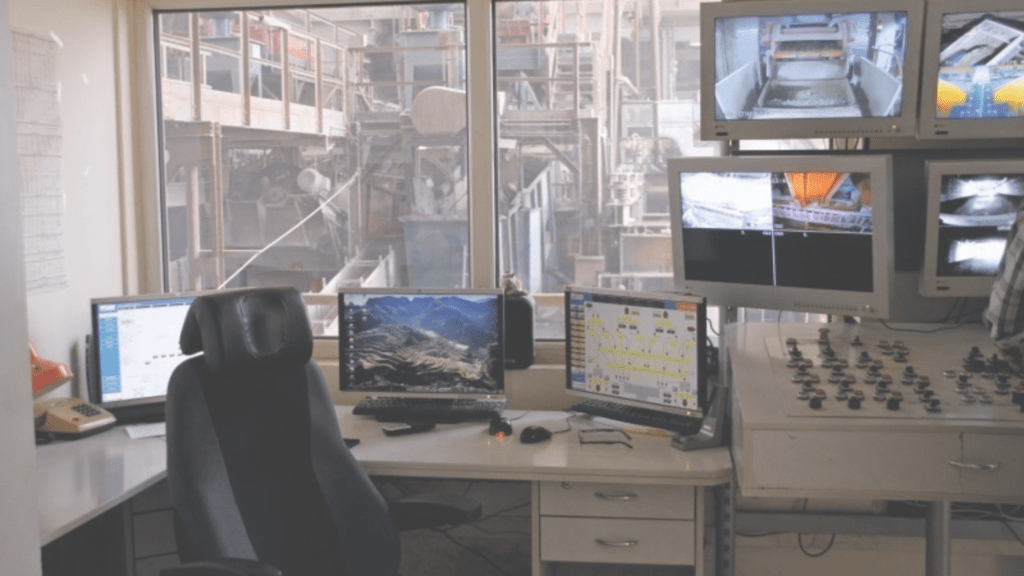

When working in a mining control room or building, dust and other unwanted particles in the air can pose serious problems. These contaminants can damage equipment, compromise safety, and decrease productivity. Controlling the level of dust is essential for maintaining a clean and efficient workspace. In this article, we will explore how Air-Cleaning Blowers (ACBs) can effectively remove dust and particles in mining control rooms, ensuring a clean and safe environment.

Why is Dust Control Important in Mining Control Rooms? Mining control rooms are at the heart of operations, overseeing critical processes and ensuring the safety of personnel and equipment. Dust and other particles in the air can negatively impact the performance and longevity of equipment, leading to costly repairs and downtime. Additionally, excessive dust can pose health risks to control room operators and result in safety hazards.

The Air-Cleaning Blower Solution

1. Removing Dust and Particles to Keep Equipment Clean

Air Cleaning Blowers (ACBs) are specifically designed to remove dust and particles from the air, effectively safeguarding control room equipment. By using a combination of innovative filtration technologies, ACBs capture and eliminate airborne contaminants before they can settle on sensitive equipment surfaces. This helps to extend the lifespan of vital control room equipment while minimizing maintenance requirements.

2. Keeping Mist and Humidity Out of Control Rooms

In addition to dust, mist and humidity can also pose problems in mining control rooms. ACBs are equipped with built-in dehumidifiers and specialized filters that remove excess moisture from the air. By maintaining optimal humidity levels, ACBs prevent the formation of condensation and eliminate the risk of electrical shorts or equipment malfunctions.

3. Clean Controls in Heavy Dust Environments

Mining operations often generate high levels of dust due to drilling, blasting, and other activities. Traditional control rooms may struggle to maintain clean and functional control surfaces in such environments. ACBs excel in heavy dust conditions by continuously filtering the air and preventing dust from settling on control panels, switches, and other critical control room components. This ensures smooth operations and reduces the need for constant cleaning and maintenance.

4. Pre-Filtering Air for HVAC Systems

HVAC systems play a crucial role in maintaining a comfortable and safe environment within control rooms. However, these systems can become quickly clogged with dust, reducing their efficiency and lifespan. ACBs serve as pre-filters, removing a significant amount of dust particles from the air before reaching the HVAC system. This not only improves the air quality but also extends the service life of costly HVAC equipment.

5. Pressurizing Control and Electrical Enclosures

Control and electrical enclosures are prone to dust infiltration, which can lead to equipment failures and malfunctions. ACBs feature a pressurization function that creates a positive pressure within these enclosures, preventing dust entry. By maintaining a dust-free environment, ACBs enhance equipment reliability, reduce breakdowns, and minimize the need for frequent maintenance.

The presence of dust and particles in mining control rooms can significantly impact equipment performance and operator safety. ACBs offer an efficient and effective solution to remove dust and contaminants from the air, ensuring a clean and safe working environment. By investing in ACBs, mining companies can improve equipment longevity, reduce maintenance costs, and enhance operational efficiency. Take control of your control room environment by utilizing Air-Cleaning Blowers and experience the benefits they offer.

for more information contact Amber at amurphy@aircleaningblowers.com

Check out our related article on controlling mining dust in trucks, excavators, and draglines here.