Electrical cabinets and enclosures play a crucial role in various industries, including food processing plants and mines. However, these areas are often exposed to high levels of dust, which can lead to numerous problems such as overheating, electrical shorts, malfunctions, and premature failure of components. To combat dust in electrical enclosures, several solutions have been proposed in the past, including dust collection systems and regular cleaning. While these methods have their merits, they also come with drawbacks that can be costly and time-consuming. Our Air Cleaning Blowers present an innovative solution that not only effectively eliminates dust but also provides added benefits for a more efficient and productive environment.

Current Solutions: Dust Collection

One commonly employed solution for preventing dust infiltration in electrical enclosures is the installation of dust collection systems. These systems are designed to capture and remove airborne dust particles. However, while they can be effective in controlling dust in larger spaces, they can be prohibitively expensive and require considerable space for installation. Moreover, even with effective dust collection, there is still a risk of dust finding its way into cabinets located near the source. Even worse, if these systems are not properly maintained, there is an increased risk of fire and explosion.

Fixed Schedule Cleaning

Another approach to dust elimination is to regularly clean the electrical cabinets or enclosures. This involves tasks such as vacuuming, wiping down surfaces, or blowing out the cabinets with compressed air. While this method can help in maintaining a dust-free environment, it requires manpower, time, and strict adherence to a maintenance schedule. This can be a tedious and time-consuming process, especially in large industrial settings where numerous enclosures need to be cleaned regularly.

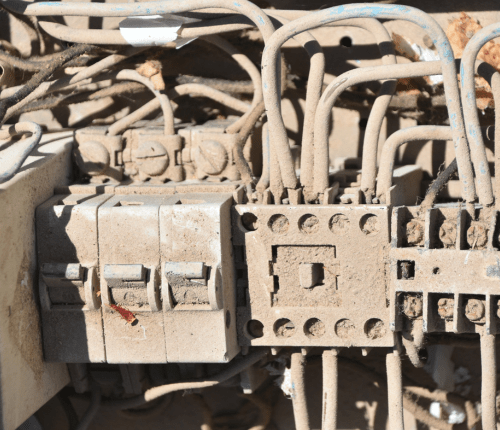

Living with the Problem

Unfortunately, some plants choose to ignore the dust issue and deal with emergencies as they arise. This approach leads to maintenance personnel being constantly diverted and production being disrupted, resulting in substantial financial losses. Unplanned maintenance not only hampers existing schedules but also leads to the idling of equipment and personnel until repairs are completed. Moreover, downstream processes and product shipments are also delayed, impacting overall plant efficiency and customer satisfaction.

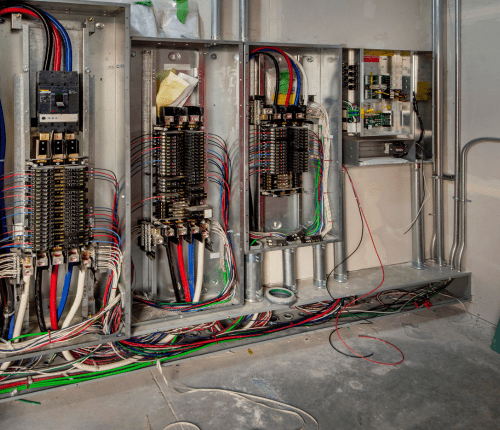

Our Solution: The Air Cleaning Blower

Unlike traditional systems, our innovative Air Cleaning Blower offers a revolutionary solution to prevent dust in electrical enclosures. Our system can be adapted to specific size requirements, including smaller systems, making it highly versatile. It removes dust without the need for media filters and blows in clean air, effectively eliminating the dust issue and aiding in proper ventilation. This unique approach not only prevents dust-related malfunctions but also enhances the overall cleanliness and air quality within the facility.

By using our Air Cleaning Blower, plants can experience the following benefits:

- Cost-Efficiency: Our system provides a cost-effective solution compared to expensive dust collection systems. It eliminates the need for constant filter replacement, reducing maintenance and associated costs.

- Energy Savings: As our Air Cleaning Blower eliminates the need for media filters, it requires less energy consumption compared to traditional systems. This translates into cost savings and reduced environmental impact.

- Improved Productivity: By preventing dust-related malfunctions and minimizing unplanned maintenance, our system helps plant processes run smoothly, maximizing productivity and minimizing disruptions.

- Enhanced Safety: With dust-related fire and explosion risks significantly reduced, our solution improves overall safety in the plant environment. This leads to a safer working environment for personnel and mitigates potential property damage.

- Compliance with Standards: Our Air Cleaning Blower meets the necessary compliance standards, ensuring plants adhere to safety regulations and provide a conducive working environment.

In conclusion, preventing dust in electrical enclosures is vital for maintaining optimal plant processes and avoiding costly repair and maintenance. While conventional solutions such as dust collection systems and regular cleaning provide some relief, they come with their limitations. Our Air Cleaning Blower offers a transformative approach that effectively eliminates dust without the need for complex systems or high maintenance.

For additional information on eliminating dust in electrical enclosures contact us.