Agricultural operations produce a lot of airborne particles, including minerals, field, and barn dusts, and pollen making agriculture dust a huge issue. These dusts are mostly approximately 10 millimeters in size, which makes them capable of entering the lungs and potentially causing severe respiratory damage. Prolonged exposure to dust can result in various health issues, including pneumococcus, a lung condition that restricts breathing.

Dust also poses a threat to motors and other electrical equipment or machinery leading to significant expenses in repairs or replacements. However, the most pressing danger associated with agricultural dust is its potential to cause explosions. The accumulation of grain dust within a facility has long been recognized by farmers as a critical risk. When an enclosed space contains too much dust, even a small spark or ignition source like an overheated bearing can trigger a grain dust explosion. A dust explosion could destroy a grain elevator or mill.

It is widely acknowledged that a mere 1/8-inch layer of dust is sufficient to ignite an explosion. Annually, an estimated 10 explosions occur in the United States alone, leading to multiple fatalities each year.

OSHA and the National Fire Protection Association

Grain dust accumulation and potential ignition sources are subject to regulation under OSHA standards in order to prevent explosions. Employers have a responsibility to minimize the accumulation of dust, as failure to comply can result in significant fines. OSHA has recently imposed fines exceeding $1 million for fatal explosions that occurred within this industry.

The National Fire Protection Association emphasizes the importance of these precautions not only within grain elevators and mills but also in any facility engaged in the handling of agricultural materials. This includes facilities involved in receiving, processing, storing, or shipping dry agricultural bulk materials.

What can be done?

When making a selection for a dust collection system, you should consider the advantages offered by Air Cleaning Blowers. By doing so, you can effectively safeguard both workers and factories against the potential hazards presented by agricultural dust. We currently offer two products to address these dust issues:

Our signature product, the Air Cleaning Blower –

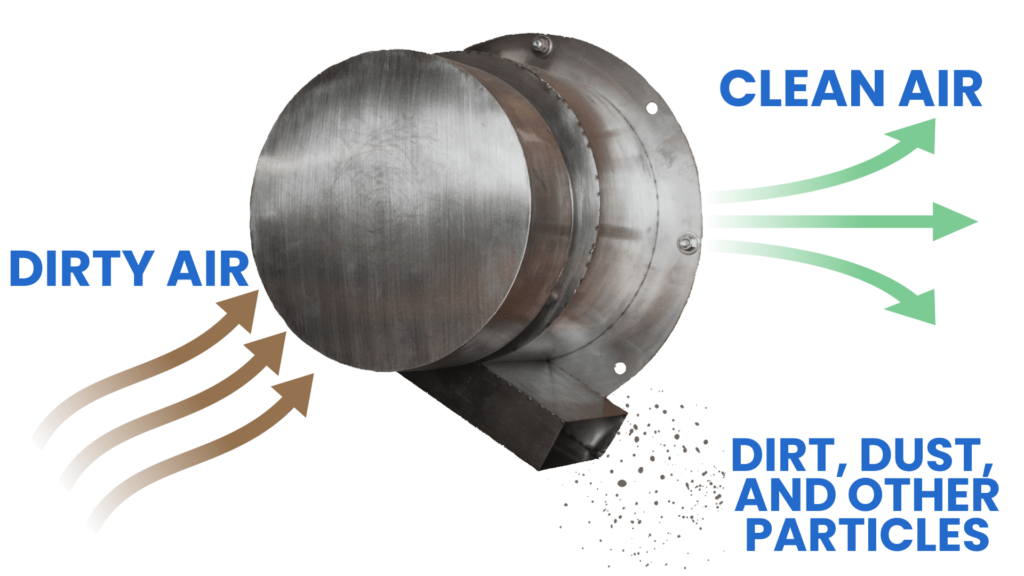

The best way to control agriculture dust is with a dust collection system. This, however, is usually an expensive undertaking. The key is to use a good efficient system. Air cleaning blowers offer a more affordable sustainable approach to solve some of these issues. Our systems remove the dust and other particles from the air, discharges them either to where they originated or through ducting to location of your choice for disposal or collection, and then blows clean air in providing clean air for equipment and workers.

The typical air filtration system uses filters that will lead to expensive maintenance costs as they get clogged and need regular filter replacements. They can also break down or run inefficiently if maintenance is deferred. The Air Cleaning Blower operates with no filter media so there is no need for replacement and very little maintenance is required. They are built to be durable in the dustiest of conditions.

The size of most agriculture dust is usually a challenge to control. Grain dust can be anywhere from 5-1000 microns. An independent lab study found that the Air Cleaning Blowers removes up to 99% of dust particles larger than 10 microns, and almost 40% of microns between 3.5-10. This means our Air Cleaning Blower can remove a significant amount of agriculture dust, most notably grain dust. Click here to see how the Air Cleaning Blower works.

The Safety Canopy

Our Safety Canopy can provide personal protection for workers. You can mount a Safety Canopy on a stand or hang it from a ceiling above workers. The Safety Canopy can be mounted on a stand or hung from a ceiling above workers. The Safety Canopy provides a cone of HEPA-filtered air that flows downward to help keep agriculture dust and other particles away from workers faces preventing them from being inhaled. Click Here to Find out More about the Safety Canopy.

Hear it directly from our Customers:

Among the many companies using our products is Mitsubshi International Food Ingredients, Inc. who source and distribute domestic and international food, custom seasoning blends, nutritional, and pharmaceutical ingredients. Plant Manager, Frank McKinney said:

“The results have been exceptional, as the unit is very easy to maintain and is effective in our dusty environment. We employ a traditional 10,000 cfm facility wide system. Therefore, in order to focus any dust collection, we would have to employ flex ducts and deal with the movement. damage, cleaning, etc. that would come with the added line – not to mention the sheer number of applications needed would undermine the effectiveness of our existing unit. The $400 per filter (16 total) costs that must be removed, cleaned and reassembled already costs us over $600 a month in maintenance and sanitation labor. Our Operators favored this unit due to its flexibility in location and no filters to change!”

For more information on how an Air Cleaning Blower can help solve your dust problems contact Amber at amurphy@aircleaningblowers.com

- Dust in Electrical Enclosures: Solutions to Win the Battle

- Powell Testimonial: Optimal Air Quality for their Control Rooms

- Carolina Ingredients: “The results have been exceptional”

- Cottonwood Clogging: A Simple Solution to Keep your Air Conditioners Safe!

- Agriculture Dust Spotlight: Protect Workers & Prevent Life Costing Explosions